Pottery and Ceramic

The art of making earthenware mud bricks with a layer of colored glazed designs and patterns to cover all kinds of surfaces of a con. struction is called tie making. Tile is an earthenware object which its width and length is different and has a glass and smooth side and it is used not only as decoration but also moisture insulation in the construction.

The word Kashi (tle) has derived from the name of Kashan City which has been well-known as the center of tile making and pottery Industry since the early Islamic period. Tile has a long antiquity and among the improvements and changes which human has achieved in the field of brick making. The first time that colored bricks were used in buildings is not clear but the samples which have been discovered in Eilam from second millennium B.C are among the first discoveries in this field.

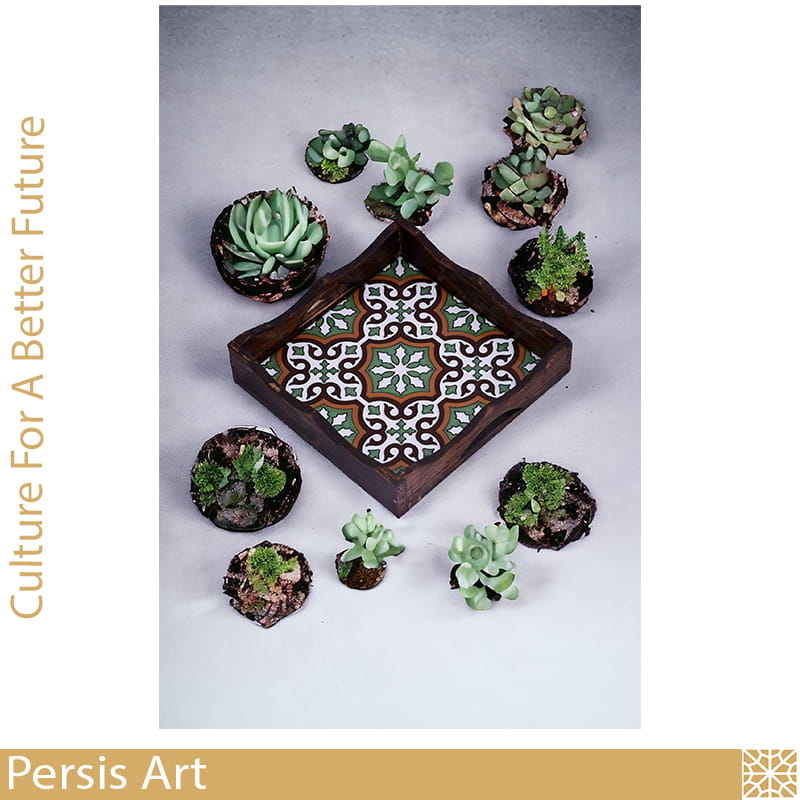

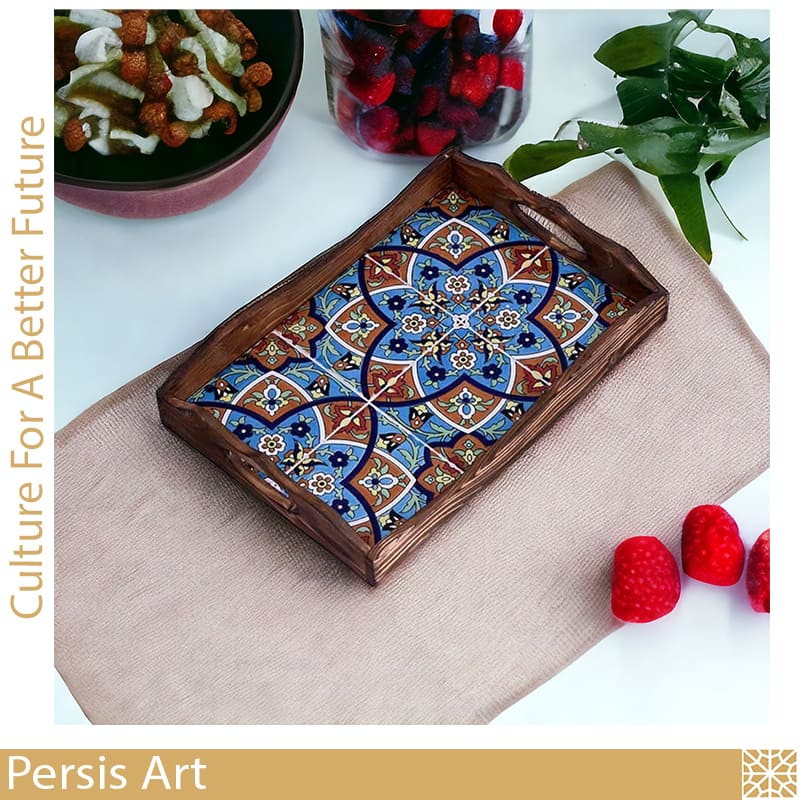

Among the works which have been built in this way in plateau of iran we can name the buildings located at Persepolis and Susa. Tie working was revived during Abbasid Caliphs period and after-wards. According to Professor Pope, for the first time glazed bles were used in the dome of Ghazvin Jame Mosque in the 12th century A D but as soon as this style was initiated, it developed quickly and within a few generations al buildings were covered beautfully with the working. Primary ties were made more with a simple cot ored glaze with geometry shapes in the brick background but following this trend pattered ties were made in the late 12th century A D Tile working is performed by two main methods of Moaragh (mosaic) and seven-color. Of course Zarinfam (golden) tie, Moag-hai tle and etc. are other kinds of tile working which are much less used. Moaragh tie is one of the simplest and the most beautiful methods for covering the construction. In this method, after baking raw mud-brick in the kin, the surface of tile is glazed with colors like blue, turquoise, green, yellow and etc. and is baked in Kin again. Then, the design in question is drawn on the paper and after being glued on the bile, extra parts are removed by an adze to obtain the desired design of the bile. Following it, all cut and tied pieces are matched together proportional to their designs and colors so that there is less empty space between them. The cut pieces are arranged on the ground to gain general design then from the back and by a metal mesh and grout it is formed as one piece, then it is prepared to be installed on different parts of the building Due to hardship of making this type of tile, seven-color tie was made to cover the whole building with colored and pattered les in less time. For making seven-color tle, according to the size of design, raw ties are baked and arranged beside each other then the design is transferred by charcoal dust on the surface of tie and having painted its entire surface, it is coated by white glaze which becomes pellucid after being baked.

Designs used for seven-color tile include prayer niche, flowerpot, rosette, geometric shapes and different kinds of bird and animal de-signs. Nowadays it is seen that white ceramic is used instead of painting and coloring on raw mud-brick then the design is created on it by silk print, which technically it is far different from traditional the making not only in terms of color and glaze but also qualty.